Industrial News

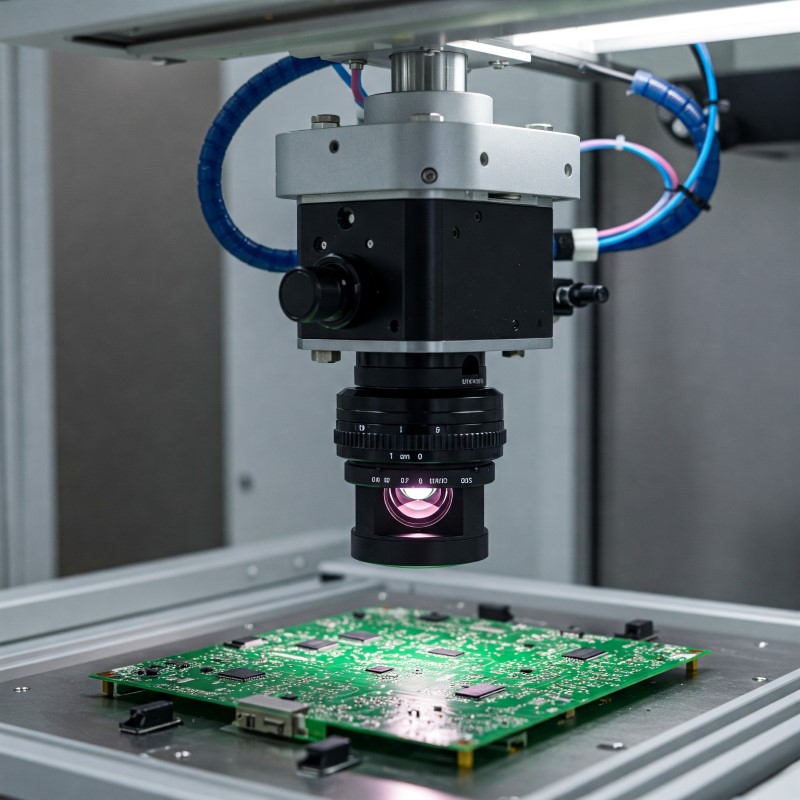

When it comes to building a high-performance machine vision system, many engineers focus on cameras and software—yet the lens is just as important. Choosing the right machine vision lens is crucial to ensuring accurate image capture, sharp detail, and reliable measurements. Whether you're inspecting circuit boards, tracking products on a conveyor, or measuring components with precision, your lens must match the demands of the application.

So how do you choose the right one? In this guide, we’ll walk through the key factors to consider when selecting a machine vision lens that delivers the clarity, consistency, and cost-efficiency your system requires.

1. Know Your Sensor Size

Match the lens to the camera sensor

Every lens is designed to support a specific sensor format—such as 1", 2/3", 1/2", etc. Using a lens with a smaller image circle than the sensor causes vignetting and loss of data around the edges. Always confirm compatibility.

2. Determine the Required Focal Length

Focal length = field of view + working distance

The focal length determines how wide or narrow the field of view is. Use simple lens calculators or formulas to define the right focal length based on how far the object is from the lens and how much area you need to capture.

3. Choose the Right Resolution

Resolution affects detail and accuracy

High-resolution applications like microelectronics or defect detection require lenses that can match or exceed the pixel resolution of the camera sensor. A low-quality lens on a high-res camera defeats the purpose.

4. Consider the Aperture and Lighting

Aperture affects brightness and depth of field

Lenses with adjustable iris (f-stop) let you control light and focus range. In automated environments, pairing the lens with proper machine vision lighting ensures clear, sharp images under consistent conditions.

5. Fixed vs. Zoom vs. Telecentric Lenses

Fixed lenses: Cost-effective and simple—ideal for most factory setups

Zoom lenses: Versatile for varying object sizes or distances

Telecentric lenses: Best for measurement accuracy and eliminating perspective distortion

Final Tip: Don’t Overbuy

You don’t always need the most expensive lens. Evaluate your system’s resolution, accuracy, and budget. Sometimes, a mid-range lens delivers excellent results for a fraction of the cost.

English

English  German

German Japanese

Japanese Korean

Korean Vietnamese

Vietnamese French

French Spanish

Spanish भारत

भारत